Verus Engineering - Front Splitter Kit - BMW G87 M2

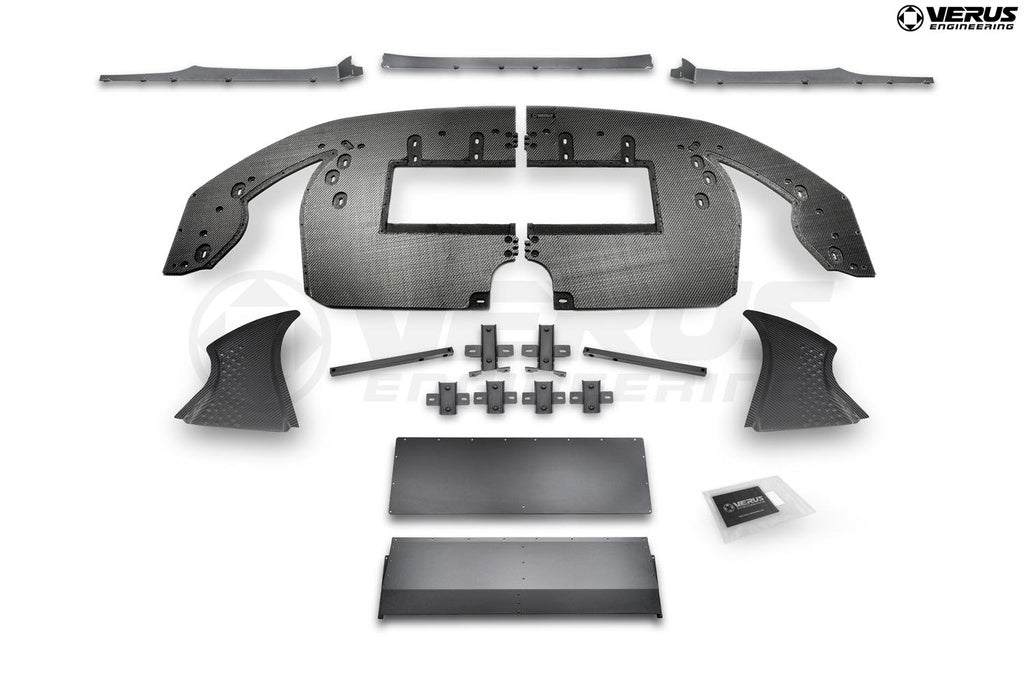

Front splitters are very effective at producing front-end downforce without increasing drag significantly. They do this by creating a large pressure delta between the top and bottom surfaces. Utilizing scan data directly from the car and CFD, we were able to produce a splitter that pairs well with our UCW rear wing and can easily handle the loads seen by the splitter. Splitter tunnels or splitter diffusers were added to increase front end downforce further than a flat blade alone. The splitter mounts to multiple chassis locations for a strong and durable mounting style. All hardware locations are recessed for improved aerodynamic performance.

During research and development, great care and focus was taken to ensure the oil cooler's exit airflow did not adversely hurt splitter performance. We offer a block off plate, an exit duct, and you can run the car with a wide open splitter as well, for varying levels of front on downforce and performance.

The splitter is produced from a carbon polyweave, which is the same material used in high forms of Motorsports. The material is not brittle, so no more issues with cracking like carbon fiber and ABS. It will not grab and bend under the car like aluminum units either. The material is also lightweight and stiff; which makes it a great splitter material

The air dam is used to bring the splitter flat with the vehicle's underbody and improve performance further. The air dam is produced from sheet aluminum and then powder coated black for durability.

Front splitters, when designed properly, greatly increase front-end grip. Utilizing state-of-the-art analysis software, we were able to extract more performance from the front splitter and air dam combo through an iterative design process. We were also able to properly size the front splitter and dive planes to counteract the rear wing; creating a safe and effective aero balance for owners. This is important as an unbalanced car is more difficult to drive at the limit. During development we studied the oil cooler's interaction with the underbody airflow and created a block off plate and exit ducting to improve performance regardless of which scenario you decide to run.

The front splitter is part of our Ventus 2 Aerodynamics Packages for the G87 BMW M2. The Ventus 2 kits boost downforce significantly from the factory vehicle. The goal was to create a package that dramatically improved the aerodynamic performance from a factory BMW M2 in a safe and balanced package for the typical track/HPDE enthusiast. Another goal was to retain street-ability from the aerodynamic components; with reasonable front splitter stick out and rear wing widths.

Specifications

- Front Splitter is Manufactured From Carbon Polyweave, Offering Superior Strength, Weight, Durability, and Appearance to Many Other Options

- Will Not Grab and Bend Surfaces Like Aluminum Units

- Will Not Crack and Break Like Carbon and ABS Units

- Abrasive Resistant While Stiff

- 5052 Aluminum Air Dam

- Carbon Diffuser Tunnels

- CNC Cut and Bent Brackets

- Stainless Hardware Throughout

Features

- Greatly Increases Front End Downforce

- Produces High Downforce for Large Rear Wings

- Capable of Handling 300+ Lbs

- Constructed From Carbon Polyweave, Which Offers Strength, Low Weight, Durability, and a Great Appearance

- Same Material Used in Various Forms of Racing, Including Indy Car, NASCAR, and F1

- Splitter Diffusers designed for improved performance

- Integrated Air Dam that Follows The Front Bumper Lines Well

Vehicles Supported

BMW G87 M2